MicroProf® 300

The MicroProf® 300 is part of the high-performance and versatile MicroProf® range of equipment and is particularly used in quality assurance, development and manufacturing. The smallest deviations from the ideal surface shape must be determined contact-free without destroying the sample as the surface must be precise down to the sub-μm range. Besides roughness of the sample surface, shape is one of the most important parameters. Narrow tolerances must be precisely determined. The MicroProf® 300 is perfect for these requirements and can also be integrated into production in a fully automated way. An extensive range of sensors and the option of conduct bilateral sample inspections (TTV) make it possible to optimally and individually adapt the MicroProf® 300 to suit your measuring task at any time. Furthermore, the simple automation of measurements boosts productivity and process reliability.

The MicroProf® 300 is part of the high-performance and versatile MicroProf® range of equipment and is particularly used in quality assurance, development and manufacturing. The smallest deviations from the ideal surface shape must be determined contact-free without destroying the sample as the surface must be precise down to the sub-μm range. Besides roughness of the sample surface, shape is one of the most important parameters. Narrow tolerances must be precisely determined. The MicroProf® 300 is perfect for these requirements and can also be integrated into production in a fully automated way. An extensive range of sensors and the option of conduct bilateral sample inspections (TTV) make it possible to optimally and individually adapt the MicroProf® 300 to suit your measuring task at any time. Furthermore, the simple automation of measurements boosts productivity and process reliability.

Measuring tasks

- Roughness Step, Height

- Film Thickness, Wear

- Warp, Defect Inspection

- 3D Map, Waviness

- Bow, TTV

- Layer Stacks, Bumps

- Flatness, Topography

System characteristics

- Full multi-sensor capability

- Integrated CCD camera with add-on illumination

- Brilliant, long-living, and energy-effi cient LED

- Based on the tried and tested FRT CWL technology

- Motorized sensor approach with high-precision axis

- Vertical stitching function to expand the height measuring range

- Control and measurement computer with TTF monitor

- Simple and effi cient control with FRT Acquire software

Benefits

- Attractive price-performance ratio

- 3D measurements with micro- and nanometer resolution

- Professional quality assurance based on precise optical metrology

- High performance and economical measuring tool

- Durable, minimal servicing and low maintenance

- Fast availability and simple operation

- Application specifi c consulting from skilled FRT experts

- Qualifi ed and worldwide operating service network

Measuring Principle

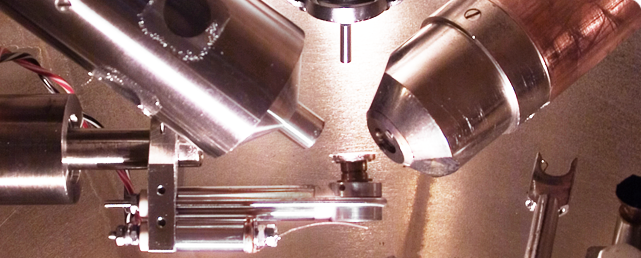

The MicroProf® 300 is one of the FRT multisensor measuring devices and can be fl exibly adjusted to customer requirements by the simple change of the sensor. Among other, the principle of the chromatic distance measurement can be used. White-light is focused on the surface by a measuring head with a strongly wavelength-dependent focal length.

The spectrum of the light scattered on the surface generates a peak in the spectrometer. The wavelength of this peak is used to determine the height on the sample. The measuring tool handles transparent, highly refl ective or even light absorbing surfaces and materials.

|

System |

|

|

Assembly |

Gantry Design |

|

Sensor |

Multi-Sensor |

|

Scanning Stage |

|

|

Travel |

415 mm x 305 mm |

|

Drive Type |

Direct Drive |

|

Bearing Type |

Crossed Roller Bearing |

|

Encoder Resolution |

50 nm |

|

Flatness |

< 2 μm / 100 mm |

|

Max. Speed |

300 mm / s |

|

Load Capacity |

5 kg |

|

z-Axis |

Motorized Axis |

|

z-Axis Travel |

50 mm (100 mm optional) |

|

System Requirements |

|

|

Environmental Requirements |

Clean, Vibration Free, Stable Temperature |

|

Input Voltage |

110 V / 220 V AC, 1 Phase |

|

Footprint (L x W x H) |

1200 mm x 800 mm x 1500 mm |

|

Weight |

approx. 700 kg |

|

Measuring Characteristics (Measuring Head) |

CWL 600 μm |

|

Measuring Range xy |

415 mm x 305 mm |

|

Measuring Range z |

600 μm |

|

Resolution (lateral) |

2 μm |

|

Resolution (vertical) |

6 nm |

Каталог приборов для трехмерного контроля поверхности FRT (Германия)